Introduction to Water Treatment Plant

The water treatment process improves the quality of the water. Thus the treated water is more acceptable for some specific end uses such as drinking, irrigation, industrial water supply, or safe removal to the environment. A water treatment plant is a place where the water treatment process is carried out.

The quality of the water monitored using several parameters such as pH, temperature, turbidity, color, alkalinity, hardness, suspended solids, etc.

The water treatment plant’s steps can vary according to the intake water’s characteristics and the required quality of the output water.

Thus, the drinking water treatment process is different than the wastewater treatment process. Water treatment is the process that enhances the quality of the water for specific ends use purposes such as drinking, industrial usage, or irrigation. The wastewater treatment process is the process that purifies the water, which is no longer acceptable for regular usage. Wastewater treated before releasing to the environment, to minimize the possible environmental damages.

The output water quality of the drinking water treatment plant should meet drinking water standards, whereas the output water quality of the wastewater should meet water discharge standards.

Process steps of a water treatment plant

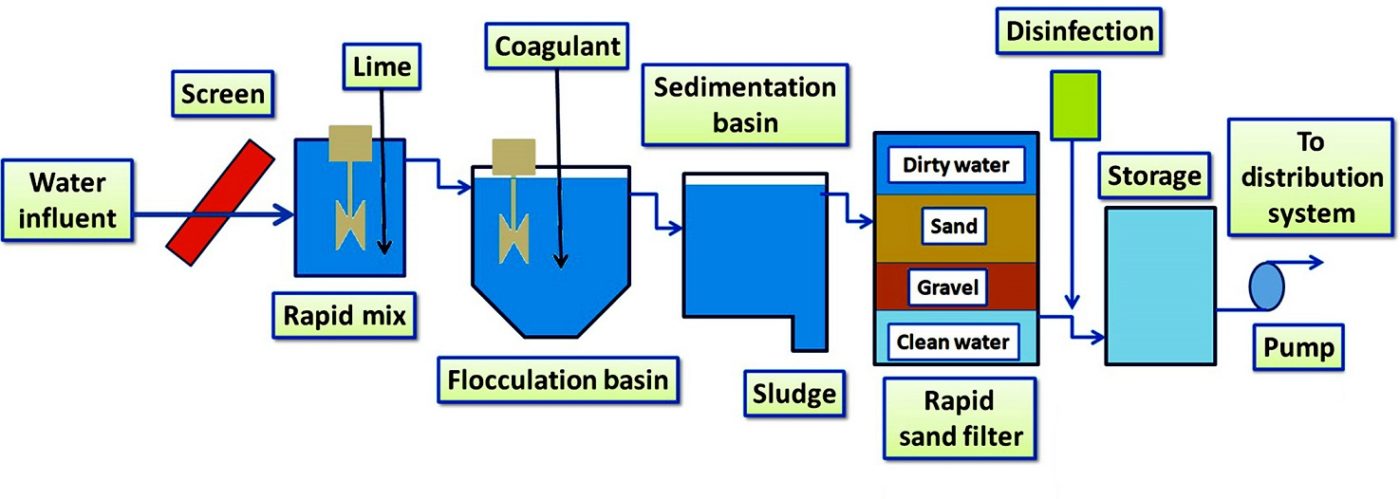

The typical process steps of a water treatment plant categorized as follows.

Preliminary Treatment

Preliminary treatment aims to remove the constituents, which causes maintenance and operational problems during the treatment process such as rags, sticks, floatables, grit, and grease.

Primary Treatment

Some portion of the suspended solids and the organic matter removes during the primary treatment.

Generally, chemical addition or filtration used for the primary treatment.

Secondary Treatment

Biodegradable organic matter and suspended solids removed during secondary treatment.

Tertiary Treatment

Residual suspended solids removed by granular medium filtration or microfiltration during the tertiary treatment. Disinfection also carried out in tertiary treatment by using several methods such as chlorination, UV radiation, membrane filtration, etc.

Drinking-Water Treatment Plant

Though water is a pure chemical compound that is naturally available on earth, it cannot be consumed directly due to contamination. Drinking water treatment plants enhances the quality of the natural water before distribution to the community. The water treatment plant’s input can be surface water (river/lake), groundwater (deep wells, shallow wells), or ocean water.

Water cannot directly consume from natural resources due to the presence of floating objects, algae, hardness, suspended solids, dissolved gasses, pathogens, taste, odor, or color.

Thus the water treatment is carried out to enhance the quality of the water prior consume.

The general steps of a drinking water treatment plant can describe as follows.

Screening

The first step of the water treatment process is screening. The collected water is first sent through a bar screen to remove large particles if present in the water. The presence of these coarse solids can cause operational and maintenance problems during the treatment process.

The screens which are operated in a water treatment plant can be classified as follows.

- Configuration – Bar Screen Mesh Screen

- Opening Size – Coarse, Fine, Micro

- Screen Surface – Moving, Fixed

- Cleaning Method – Manual, Mechanical, Raked, Water Jet

After screening, water flows to the coagulation tank where chemical addition carried out.

Coagulation/ Flocculation

The next step of the water treatment process is coagulation and flocculation. Generally, Aluminum sulfate (alum) added as thickening agents for drinking water treatment. Rapid mixing, while adding coagulant, ensures quick and thorough mixing. The objective of coagulation is to turn the small particles into larger flocks, either as precipitates or suspended particles.

Then a flocculant added to form flocs from the suspended particles. Generally, a polymer added as the flocculating agent. Slow mixing carried out in the flocculating tank to allow the flocs to grow and gain weight. These flocs will be easier to remove by either sedimentation or filtration.

There are several advantages of coagulation and flocculation. It reduces the time required to settle down suspended solids. And also, it is beneficial in removing fine particles, which will be very difficult to remove otherwise. Coagulation is also very useful in eliminating many protozoa, bacteria, and viruses.

Sedimentation

The next step of the water purification plant is sedimentation. The chemical added water then sent to a large sedimentation tank where flocs settled at the bottom of the tank, and the clear water from the top is then pass through a filter. Water flows very slowly in the sedimentation tank. Because a slow flow rate is favorable to settle down massive flocs particles to the bottom.

Filtration

The treated water from the flocculation tank then sent to the filtration. In the filtration process, the particulate matter from the water removed by forcing the water to pass through a porous media. The particles that removed from the water during filtration depend upon the size of filters that used. These filters can be varying according to the composition (Sand, Granular, Activated Carbon), as well as the pore size.

Suspended impurities in the water collected by filtration and enhance the effectiveness of the disinfection. The filters frequently cleaned by backwashing to maintain a productive output from the filter media.

Though filtration can remove a large number of contaminants in a water treatment plant, disinfection is a must to produce drinking water, which is safe to consume.

Disinfection

The final step of the drinking water treatment process is disinfection. Disinfection is the destruction or inactivation of harmful microorganisms (pathogenic organisms) in water. It can do either using a chemical method or a physical method such as UV radiation, reverse osmosis, or chlorination.

The most commonly used disinfection method is chlorination, as it is a very effective disinfection method. Chlorine is a potent oxidizing agent. It reacts, oxidizes some of the essential systems of microorganisms, and then inactivates or destroys them. The residual concentrations of the chlorine will prevent possible microbial contamination during the water distribution system.

Then the treated water collected to the distribution tank after disinfection, which connected to the distribution system.

The quality of the treated water should always monitor before distribution by considering the parameters such as pH, temperature, turbidity, color, alkalinity, hardness, suspended solids, etc.

Pingback: Reverse Osmosis for Water Treatment - Pros and Cons - Design of a RO

Pingback: Why Boiler Water Treatment is Required - ARHSE - Chemical Engineering