An orbit valve is a type of valve that is used to control the flow of fluids in industrial applications. These valves are designed to be highly reliable and durable, and they are often used in applications that require precise control over the flow of fluids.

Orbit valves are typically constructed from a combination of materials, including metals such as steel and brass, as well as various types of plastics and polymers. The body of the valve is typically made from a strong, corrosion-resistant material, such as stainless steel or brass. The internal components of the valve, such as the stem and the disc, are typically made from a softer material that is less likely to wear or corrode.

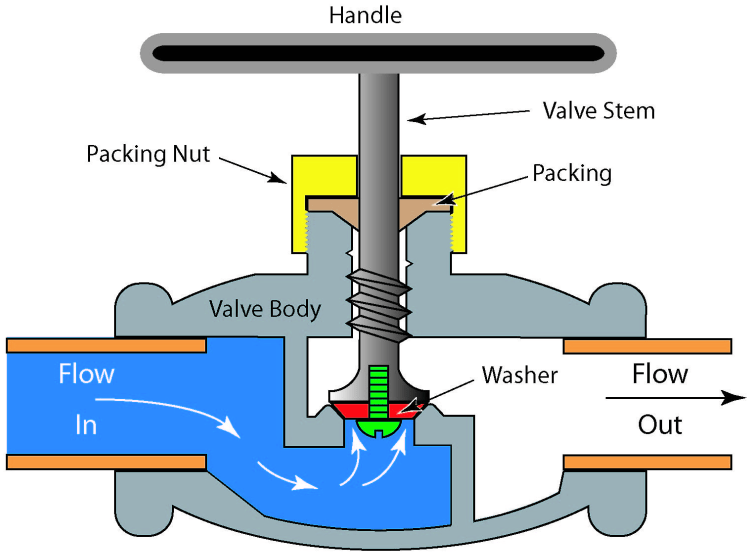

The basic design of an orbit valve consists of a body, a stem, and a disc. The body of the valve is connected to the fluid system, and it contains the internal components of the valve. The stem is the part of the valve that connects the disc to the actuator, which is used to open and close the valve. The disc is the part of the valve that actually controls the flow of fluid through the valve.

There are several different types of orbit valves, including globe valves, gate valves, ball valves, and diaphragm valves. Each type of valve has its own unique design and function, and they are used in different types of industrial applications.

Globe valves are typically used in applications where precise control over the flow of fluid is required. These valves have a disc that is attached to the stem by a linkage, and the disc is able to rotate to adjust the flow of fluid through the valve. Globe valves are often used in applications such as flow control and pressure regulation.

Gate valves, on the other hand, are typically used in applications where the flow of fluid needs to be completely shut off or opened. These valves have a disc that is attached to the stem by a hinge, and the disc is able to move up and down to control the flow of fluid through the valve. Gate valves are often used in applications such as shut-off valves and check valves.

Ball valves are similar to gate valves in that they are used to control the flow of fluid, but they have a ball-shaped disc that is able to rotate to control the flow of fluid through the valve. Ball valves are often used in applications such as flow control and shut-off valves.

Diaphragm valves are typically used in applications where the fluid being controlled is highly viscous or abrasive. These valves have a flexible diaphragm that is able to move up and down to control the flow of fluid through the valve. Diaphragm valves are often used in applications such as slurry control and chemical processing.

In addition to these basic types of orbit valves, there are also a number of different variations and sub-types of valves that are designed for specific applications. For example, there are high-pressure valves, low-pressure valves, and valves that are designed for use in extreme temperatures or corrosive environments.

Orbit valves are a crucial component in many industrial systems, used to control the flow of fluids in a precise and efficient manner. The choice of the type of orbit valve depends on the specific application, and the valve must be chosen based on factors such as pressure, temperature, and the characteristics of the fluid being controlled.