Classifications

The General Function of a valve is to control the flow of a liquid, slurry, or vapor in a piping system. The process takes place by obstructing the fluid pathway utilizing a disc or a seat of the valve. Selecting the ideal valve type regarding the need in the process is quite essential. There are a few types of valves, depending on specific criteria.

Classification of valves considering the Function

- Considering the function of the valve, they can be divided into

- On / Off,

- Control,

- Non-return valves, and

- Relief valves.

- The main purpose of an on/off valve is to stop the fluid flow as quickly as possible.

- There may be instances where there is a requirement to control the flow. This can be achieved by control valves. Here the flow rate is determined by the valve position in the flow path. However, there are fully close and fully open positions in control valves as well. Hence they can act as on/off valves as well.

- Non-return valves will only allow the fluid flow to occur in a specific direction. There are various occasions where industries need to avoid the backflow of a liquid. In such cases, a Non-return valve is very much useful.

- High pressure generated within a system can damage pipes as well as other devices. Having relief valves in key positions can solve this issue.

| On/Off (Shut off) | Control (Regulation) | Non Return (Check) | Relief |

| Gate Valve | Globe Valve | Lift Check Valves | Pressure Relief Valves |

| Ball Valve | Diaphragm valve | Swing check Valves | |

| Pug Valve | Butterfly Valve | ||

| Globe Valve | Needle Valve | ||

| Diaphragm valve | Plug Valve | ||

| Butterfly Valve |

Classification considering the Motion

There is another common classification based on the motion of the closing element of the valve. Some Valves contain closing elements that travel in a linear direction. These are called Linear Motion valves. Some valves contain closing members that travel in a circular direction. Hence they are categorized under Rotary Motion types. Regardless of the classification, it is highly important to choose the valve type according to the operation.

| Linear Motion | Rotary Motion |

| Gate Valve | Plug Valve |

| Globe Valve | Ball valve |

| Diaphragm valve | Butterfly Valve |

| Pressure Relief Valves | Swing Check valve |

We will now take a look at the operations of common types of valves.

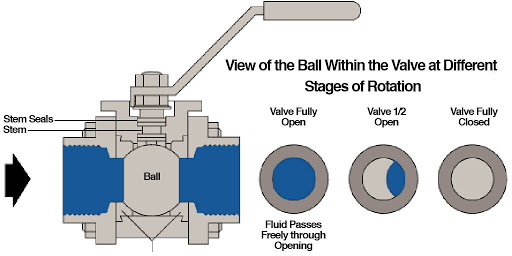

Ball Valve

The ball valve comes under on/off valves and circular motion type. There is a hollow sphere connected to a lever. As the lever comes in parallel to the flow, the hollow in the sphere will come in the direction of the flow. This allows the flow to pass through the valve.

When the lever is rotated by 90 degrees lever will become perpendicular position to the flow. Hence the sphere will come in the direction of the flow to restrict the flow. These types of valves have become the go-to on/off valve due to their lifetime and the ability to provide very good resistance to an incoming flow.

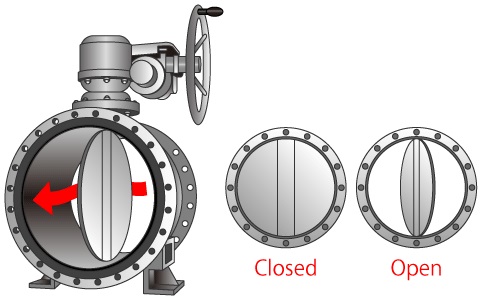

Butterfly Valve

The operation of the butterfly valve is quite similar to that of the ball valve. Here valve has a disc as the closing element, unlike the ball in the ball valve.

The lever of the valve has the ability to control the position of the valve. When the disc comes in parallel to the flow valve, it will allow the flow to pass through. When the valve comes perpendicular to the flow, the disc will act as a barrier to the flow. This comes under control rotary types valves. Still, flow control isn’t all that accurate compared to other control valves.

These types of valves have benefits such as requiring less space, low cost, and quick response. On the other hand, there are few drawbacks such as pressure loss and the requirement of high torque

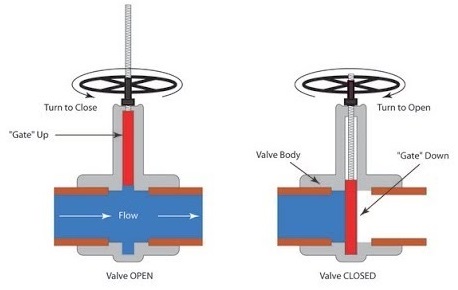

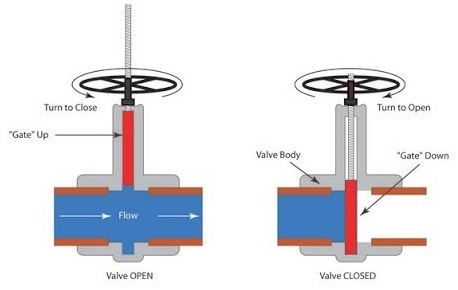

Gate Valve

The gate valve comes under on/off linear motion. It should only be used for shut-off operations. Though the structure might look like a control valve, using it as a control valve can considerably drop the pressure, which isn’t ideal.

Here a gate in the form of a disc is combined with the stem of the valve. As the steam travels with the aid of the valve, the handle disc will automatically travel in linear directions.

In contrast to the ball valve, the valve handle must be rotated quite a few times to close or open the valve fully. Hence the operation is comparatively slow. Still, there are certain instances where piping systems require the slow operation of the on/off valve. Therefore in such instances, these types of valves are vital.

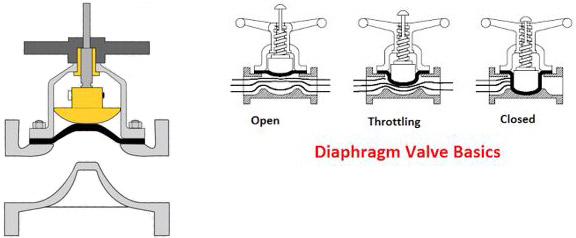

Diaphragm Valve

The operation of this type is almost identical to that of gate valves except for the diaphragm valves’ ability to regulate flows. Here the closing element of the valve is a diaphragm. As the valve handle rotates, the diaphragm will travel in a linear direction. At the end of the process, the diaphragm will settle on top of a valve seat to stop the flow of the fluid.

There are two types of diaphragm valves in the form of weir type and straight type. The main advantages of this type are its ability to control the flow, its ability to use against corrosive fluids due to the diaphragm is made out of rubber, and the structure enabling it to use against sticky materials. There are drawbacks with these types of valves such as pressure loss and inability to use in high-pressure applications.

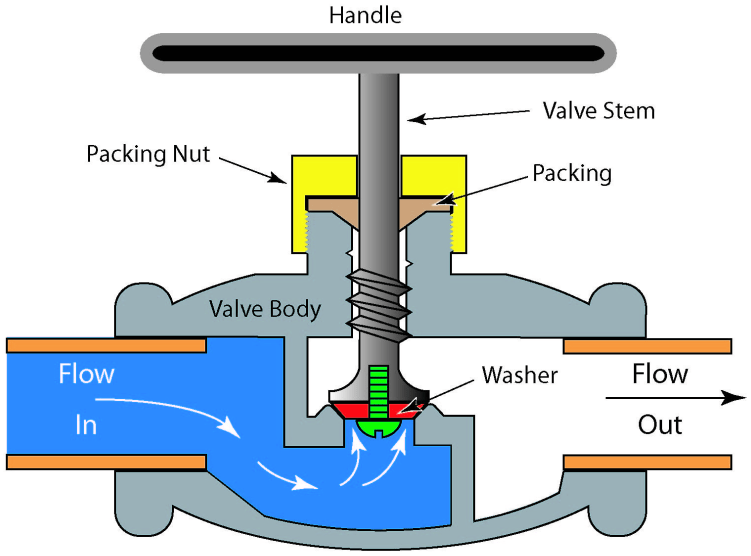

Globe Valve

The operation of the valve and the working principle is very much similar to the Diaphragm valve. Here a disc connected to the stem of the valves travels in a vertical direction. At the fully close position, the disc will sit on a ring to seal the flow.

At different positions of the disc, the flow will regulate as well. Since the flow will divert to a vertical flow from a horizontal flow, any contamination in the inflow will almost neglect to enter the valve. Despite the unique advantages, this type of valve has a considerable pressure drop.

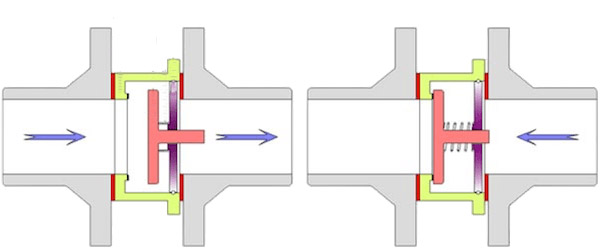

Non Return Valves

Their function is quite different from the rest of the types of valves. These valves will enable the flow in a given direction, and it will resist the fluid that tries to flow in the opposite direction. Here the working principle of the valve depends on the input pressure to the valve. When the pressure increases from the inlet, the valve will expand to allow the flow. On the other hand, when the pressure increases from the undesired direction valve will close automatically to stop the flow in the direction. Depending on the closing element, there are a few types of non-return valve types. Spring type and ball type are the most common types among them.

Let’s consider a spring type to understand the process. As shown in the picture, when the input is good enough to overcome the force of the spring, the disc will allow the fluid to pass the valve. The disc will rest in a valve seat, and there is enough space to progress the flow in the direction. Whenever there is any pressure from the other side, the disc will move to the left direction, as shown in the 2nd picture. Here the valve gets sealed, and fluid has no spaces to escape. Hence any backflow will not be allowed.

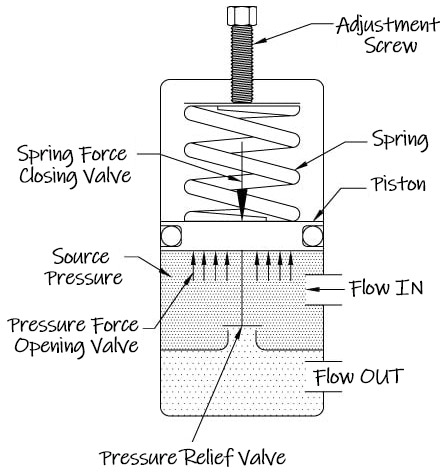

Pressure Relief Valves

The sole function of this valve is to provide safety to the system. Pressure relief valves can be a handy selection in systems that has the tendency to increase the pressure rapidly. In normal circumstances, the valve will be in a closed position. Any pressure beyond the design pressure will lift the piston of the valve. Thereby the valve will enable some portion of the fluid to flow out of the system. This will decrease any unintentional pressure. When the pressure comes back to its normal conditions, the valve will close once again to enable the flow in the system as usual.