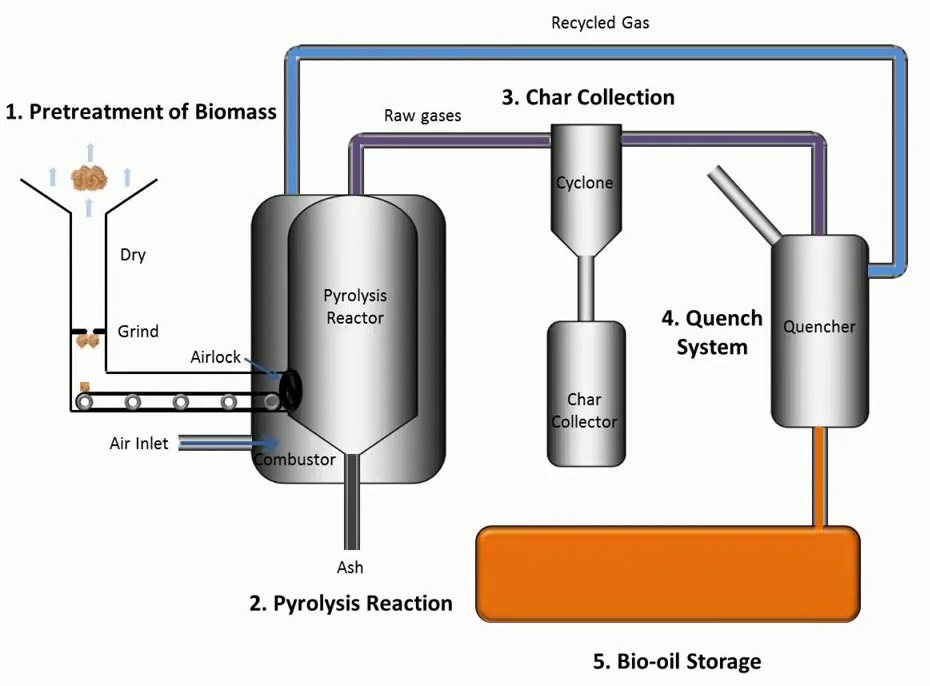

Pyrolysis is a chemical process that involves the breakdown of organic materials through the application of heat in the absence of oxygen. This process is commonly used in the waste management industry to convert waste materials into usable products, such as biochar, syngas, and bio-oil.

One of the key benefits of pyrolysis is that it allows for the conversion of waste materials into valuable resources. It is possible to improve soil fertility and increase crop yields by using biochar as a soil amendment. It is possible to use syngas, which is a mixture of carbon monoxide and hydrogen, to generate electricity. And bio-oil, a liquid byproduct of the pyrolysis process, can be further refined into a variety of chemicals and fuels.

There are several different types of pyrolysis, each with its own unique characteristics and applications. One common type of pyrolysis is slow pyrolysis, which involves the breakdown of organic materials at relatively low temperatures (around 400-600 degrees Celsius) over a period of several hours. This type of pyrolysis is typically used for the production of biochar.

Another type of pyrolysis is fast pyrolysis, which involves the breakdown of organic materials at higher temperatures (around 500-700 degrees Celsius) over a shorter period of time (typically a few minutes). This type of pyrolysis is commonly used for the production of bio-oil.

Another form of pyrolysis is called wet pyrolysis, which involves the breakdown of organic materials in the presence of water. This type of pyrolysis can be used to produce hydrogen gas, which can be used as a clean-burning fuel for power generation. The process of wet pyrolysis is also commonly used to produce biofuels, such as bioethanol and biodiesel.

Finally, there is a type of pyrolysis called gasification, which involves the breakdown of organic materials in the presence of oxygen. This process produces a mixture of carbon monoxide and hydrogen gas, known as syngas, which can be used as a clean-burning fuel for power generation. It is also common to use gasification to manufacture chemicals, such as methanol and acetic acid.

In addition to its use in the waste management industry, pyrolysis has also been explored as a potential solution for the disposal of hazardous waste materials, such as medical waste and tires. By applying heat to these waste materials in the absence of oxygen, harmful substances can be broken down and rendered harmless.

Another potential application of pyrolysis is in the field of energy production. The syngas produced through the pyrolysis of waste materials can be used to generate electricity, providing a clean and sustainable source of power. Additionally, pyrolysis can produce bio-oil that can replace fossil fuels, reducing our dependence on non-renewable energy sources.

However, there are also some limitations to the use of pyrolysis. One major challenge is the cost of the technology, as it can be expensive to implement on a large scale. Further research and development are needed to improve pyrolysis’ efficiency and effectiveness.

In conclusion, pyrolysis is a valuable process that has the potential to provide numerous benefits, including the conversion of waste materials into useful products, the reduction of the volume of waste in landfills, and the production of clean and sustainable sources of energy. While there are challenges to overcome, the continued development and refinement of pyrolysis technology holds great promise